Spotlight on Supply Chains: The Resilience of the Circular Economy

Medium Tuesday, August 4th 2020Disruptions, risk, inefficiencies and lack of resiliency have dominated the conversations about supply chains during the COVID-19 pandemic. Now, more than ever, it’s time to reimagine the existing system. Ron Gonen, CEO and Co-Founder of Closed Loop Partners and Peter Ettinger, Chief Development Officer at Bioenergy DevCo, joined Dynamo Energy Hub for a discussion on one robust solution to inefficient supply chains: the circular economy. Emily Chasan, Sustainable Finance Editor at Bloomberg, moderated the conversation.

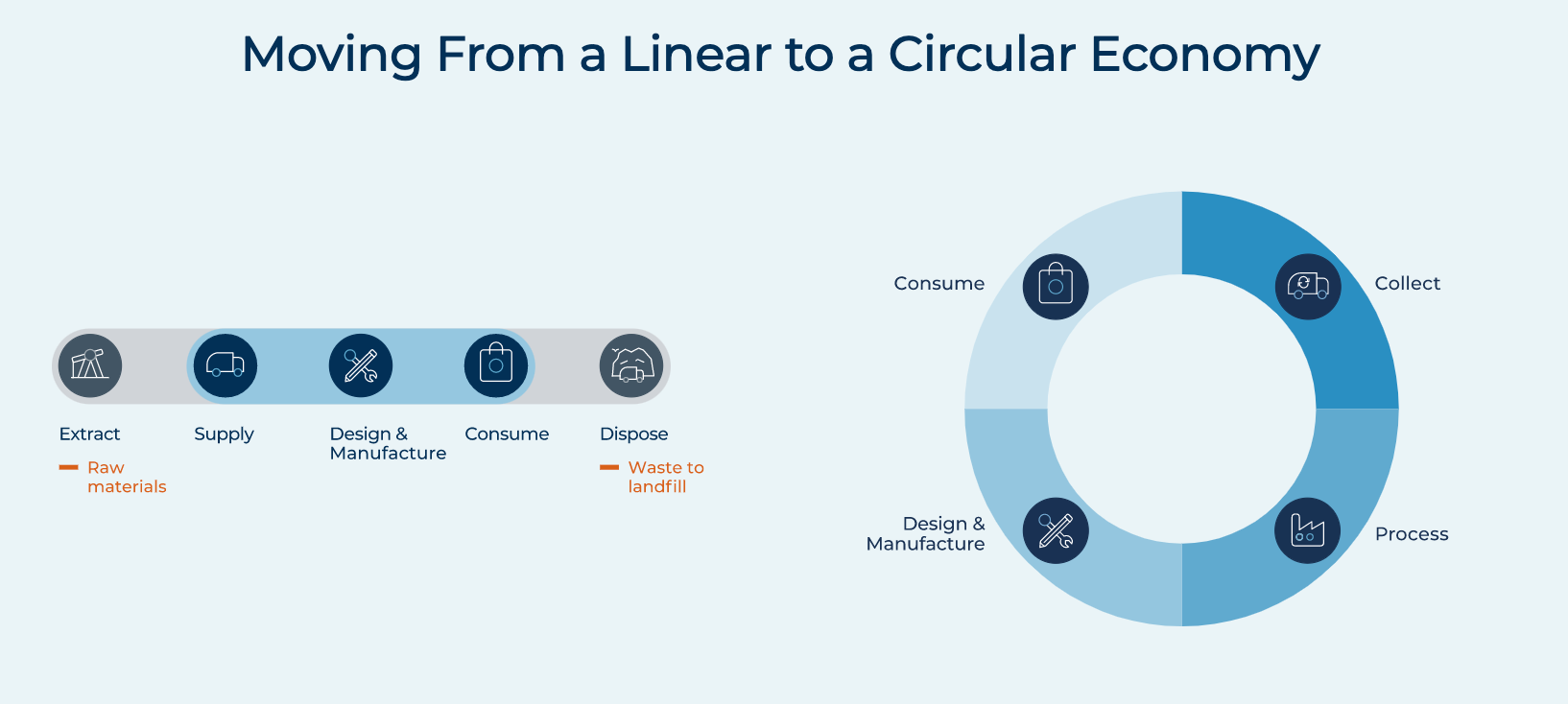

To understand what the Circular Economy is, it is first important to understand what it is not. The linear economy is a straight supply chain path from extraction to disposal. The circular economy eliminates the entanglement between extraction and disposal. Peter Ettinger of Bioenergy DevCo, an organics recycling company, describes the strength of the circular economy as a method for solving inter-economic reliance by becoming more independent, reducing waste, and spurring innovation.

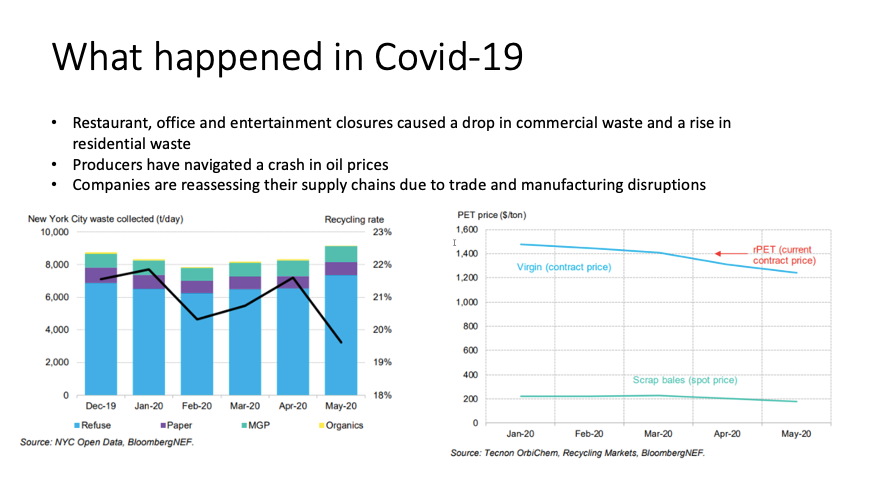

COVID-19 has challenged the status quo of supply chains. Emily Chasan of Bloomberg said, “companies are reassessing their supply chains due to trade and manufacturing disruptions all over the world.”

This shift has posed fundamental questions about the resilience of the existing linear supply chains, but, Emily continues, “sustainability and circular economy companies are still going strong.”

Ron Gonen likened the current situation with supply chains to that of building owners during Superstorm Sandy. Before Sandy, building owners were not prepared for disasters. They kept their expensive mechanical equipment in their basements, even though many knew the risks they would incur if there ever were to be a flood. Changing their business-as-usual model would have been costly and disruptive. But when the storm hit, many of those buildings were out of commission for weeks or months, and the costs of recovery were significantly higher than the costs of preparation.

Similarly, Ron said, “for the past decade people in the circular economy movement have been talking about how supply chains are bloated, inefficient, they’re wasteful and costly” and COVID has exacerbated those inefficiencies.

The answer is building resiliency among localized supply chains and eliminating inefficiencies in the form of waste.

“Consumers are demanding a better, smarter way to look at the environment and to look at business in a compatible way,” said Ettinger.

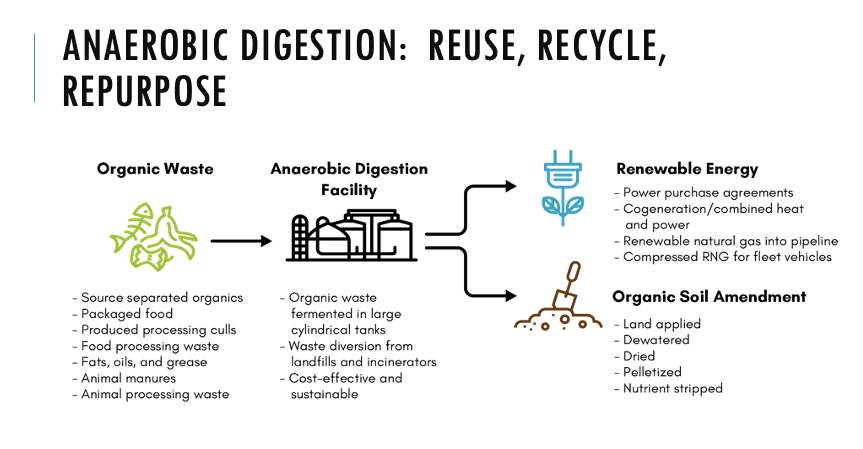

For Bioenergy DevCo, the circular economy is the core of their business model. They use anaerobic digestion to process organic waste into renewable gas that can feed directly into pipelines or compressed natural gas infrastructure. This structure eliminates the need for extraction and reduces the emissions intensity of natural gas.

And this type of energy supply chain has proven to be more resilient than the conventional model. Ettinger said that because Bioenergy DevCo operates on a localized-scale by providing energy to local municipalities, they have been far less affected by volatile energy pricing than many other energy options during COVID-19.

The resilience of circular supply chains proves to be effective in other industries as well. When asked about the resilience of virgin plastics (plastics that are being used for the first time), Ron Gonen stated “there is a certain point at which oil becomes so cheap, it’s no longer economically viable to be in that business.” And many oil-dependent businesses like virgin plastics might be going out of business because of it.

Despite thriving on a local level, both Gonen and Ettinger agree that scalability is an essential part of the circular economy. “I think scalability is the challenge to understand your client’s true goal and objective. I understand what you want, but I can’t implement it in a way that fulfills the circular economy model without adding partners…It takes a village” says Ettinger.

Thus, creating partnerships, rather than dependencies, is a prerequisite to the successful circular economy.

For obvious reasons, this type of supply chain model isn’t a win-win-win for all involved. Extractive industries and landfills will have to create new solutions. COVID-19 may be the market shock that necessitates this shift. For Ettinger, innovation is the heart of the successful transition: “What we have seen is a bunch of ingenuity around how do we repurpose our products? How do we use our products better?”

This transition will create localized benefits, according to Gonen. “We try to be a panacea to taxpayers, consumers, local municipalities and the environment. That’s who we view as our constituency.”

Want to hear it from our panelists themselves? View the recording here.

For media relations contact

Claudia Prandoni Marketing & Communications Manager